Description

Description

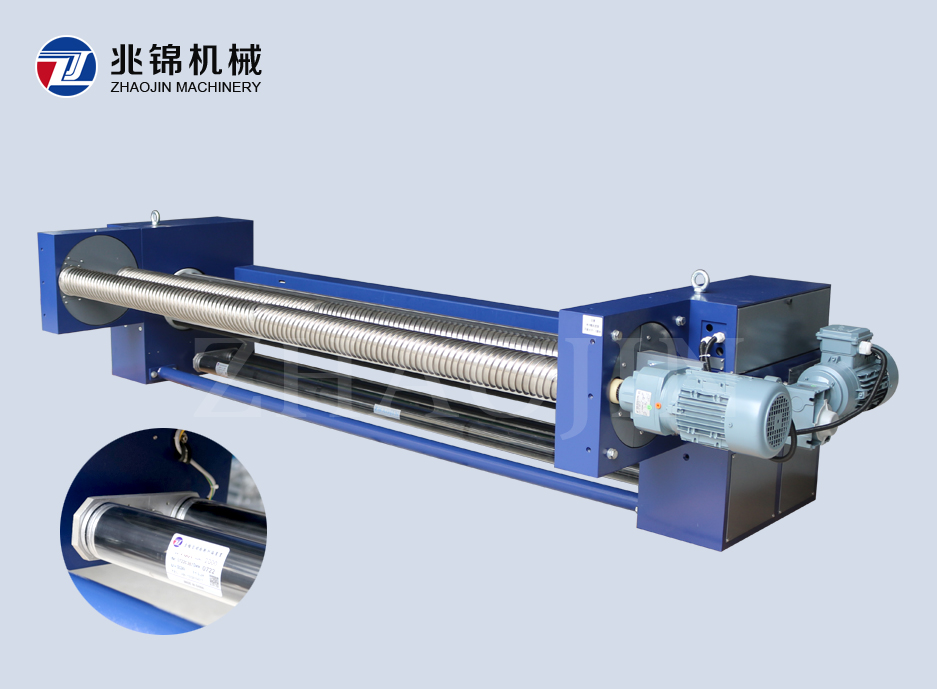

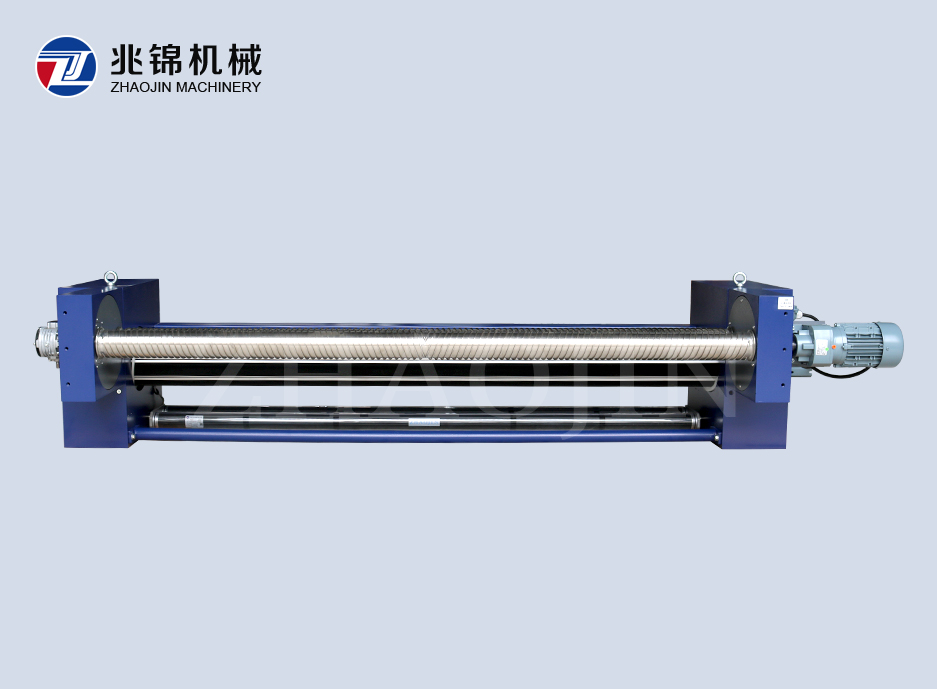

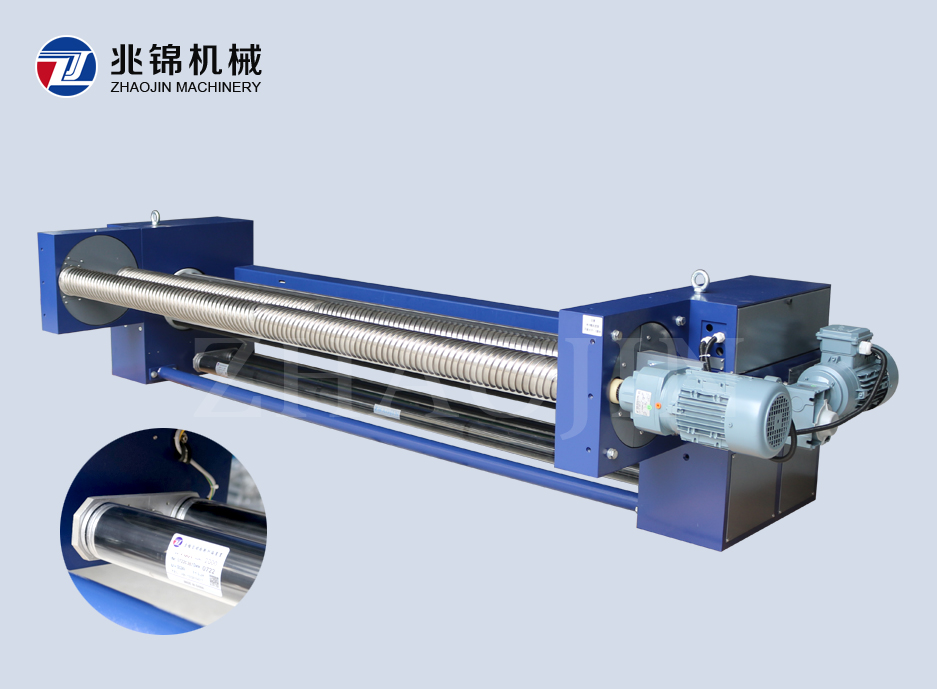

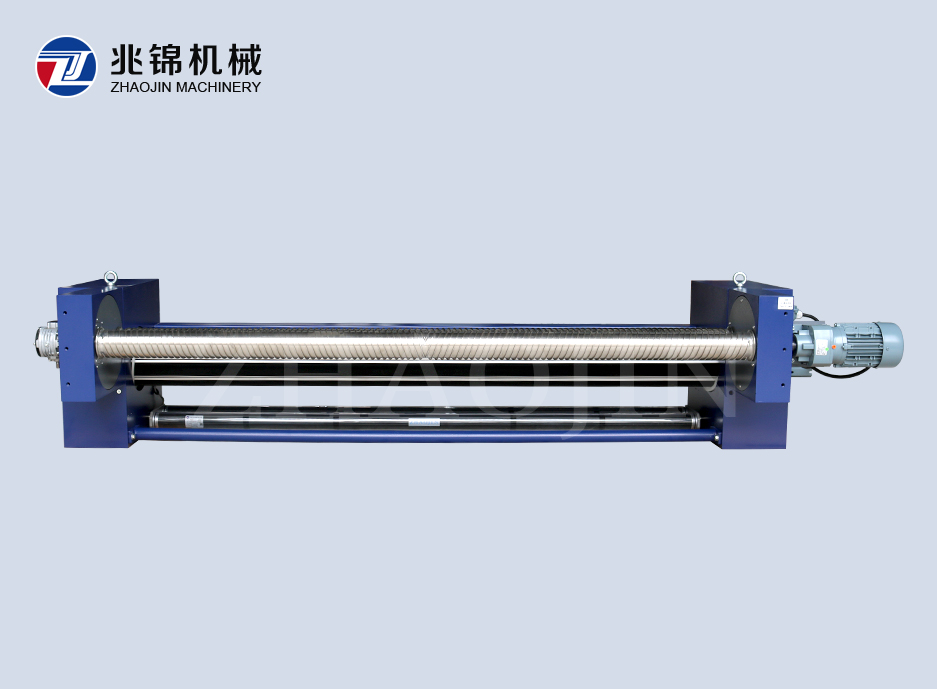

● This Device Is Used For Correcting The Deviation Of Fabrics With Open Width, And Is Suitable For Correcting And Centering Various Woven, Knitted And Other Fabrics.

● The Design Of The Translational Slider Ensures That The Fabric Maintains A Balanced Tension During The Process.

● The Sliding Bar Drum Driven By The Frequency Converter Maintains The Same Linear Speed As The Fabric, Especially Suitable For Low Tension Process Requirements.

● Equipped With A Two Roll Opening Device, The Fabric Can Be Effectively Unfolded. The Angle Of The Two Expansion Rollers Can Be Adjusted By The Handwheel To Reach Nearly 360 °, Allowing For A Wide Range Of Adjustment Between The Fabric Surface And The Expansion Contact Surface, Resulting In A Good Expansion Effect.

Technical Parameter

● Expansion Roller: Two Rollers, φ 89mm, Wire Wound φ 4. Round Or Flat Wire Is Optional

● Correction Method: Translational Sliding Bar

● Running Speed: 120m/Min

● Working Width: 1400-3600mm (In Increments Of 200)

● Infrared Detector: Full Range Detection (Center) Or Infrared Probe (Opposite Edge)

● Correction Accuracy: ± 5mm/± 3mm

● Motor: Amplification: 1.1kw; Correction Drum Synchronous Motor: 1.1kw Or Above, With Stable Gate Amplitude

● Correction Drive Method: Cylinder Drive/Electric Servo Cylinder Drive.