Description

Description

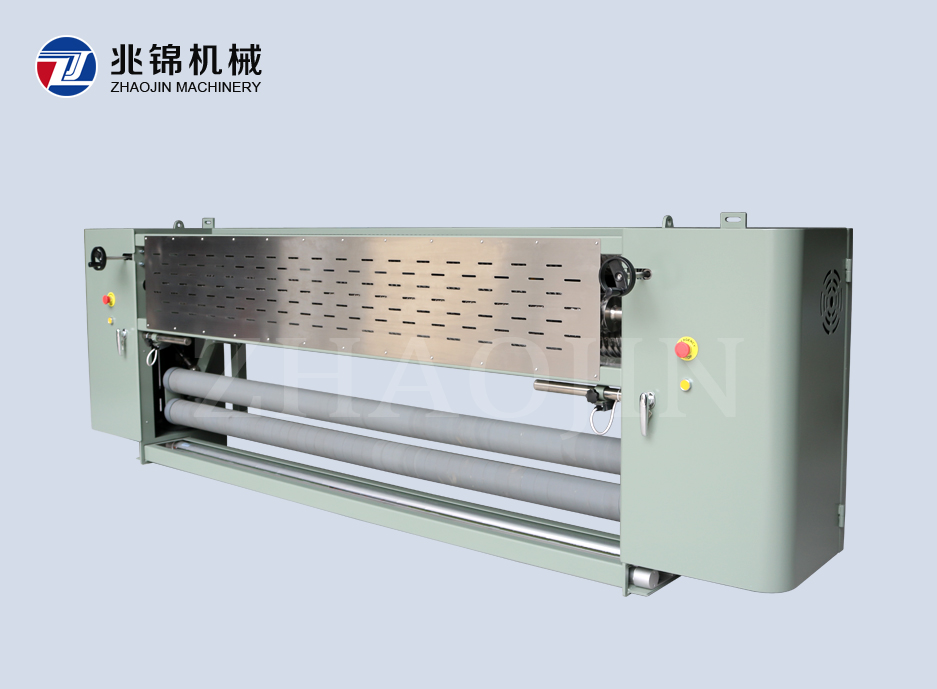

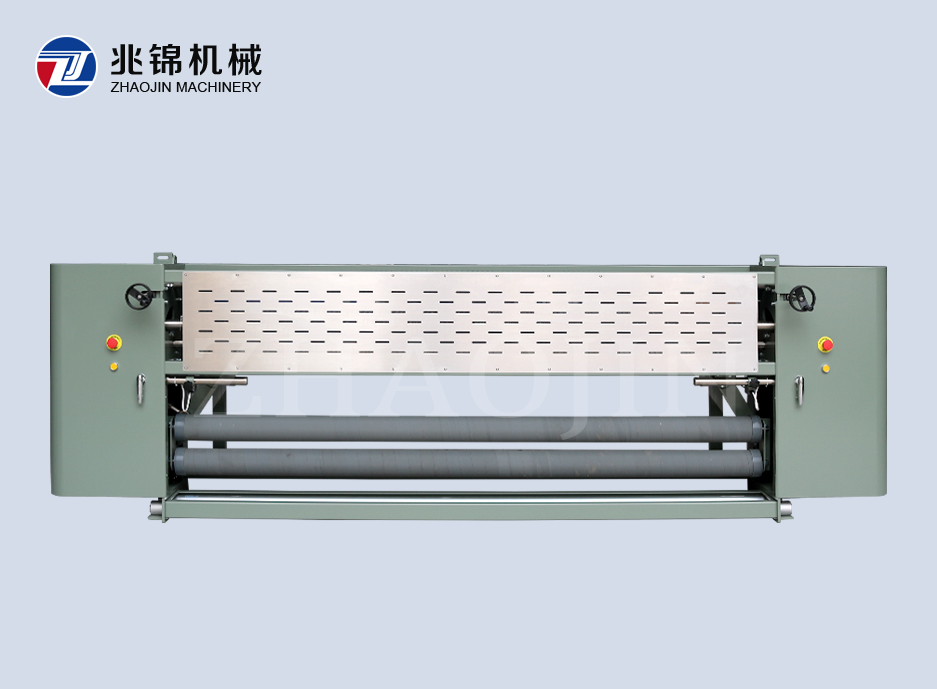

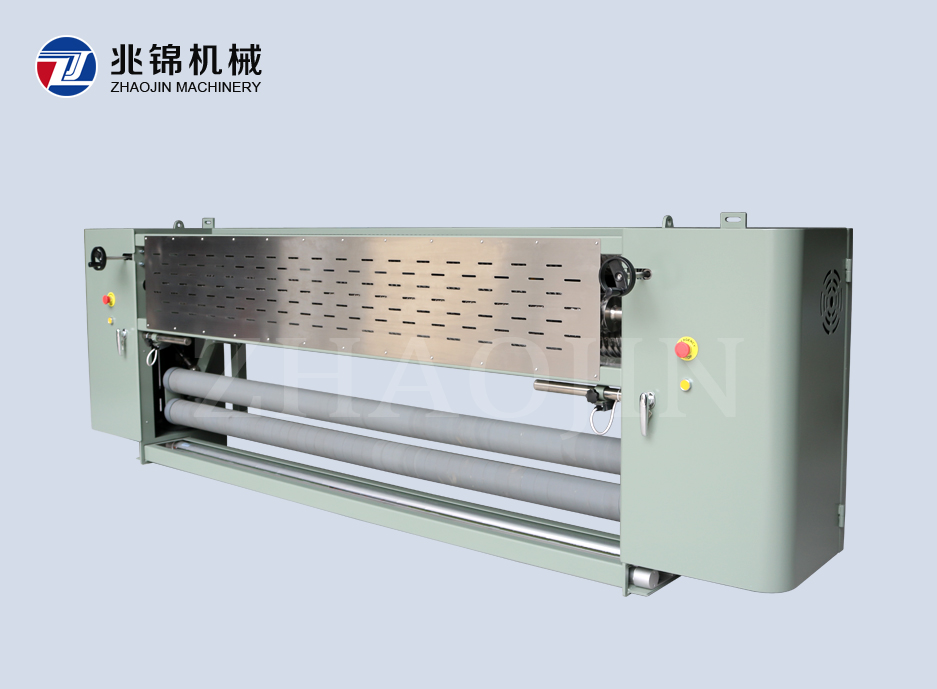

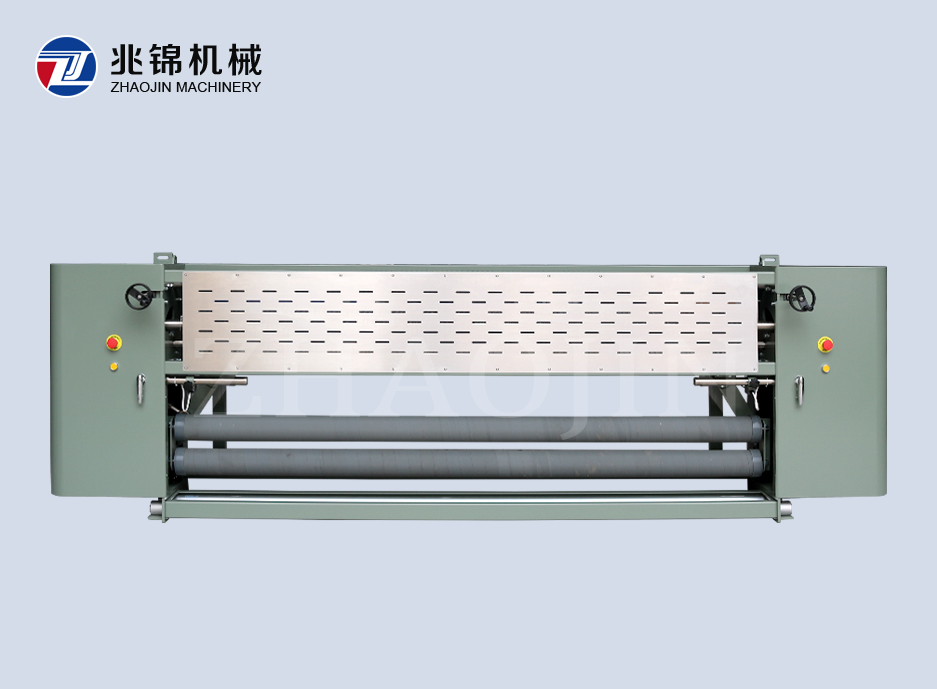

The Infrared Centering Device Is A New Type Of Product That Integrates Light, Machinery, And Electricity. This Device Is Widely Used In The Printing And Dyeing Industry, Shaping Machines, Singeing Machines, Washing Machines, Drying Machines, Printing Machines, And Other Mechanical Equipment. It Has A Strong Center Correction Function, Which Can Quickly And Smoothly Correct The Deviation Of The Symmetrical Position Of The Fabric Storage Axis, Without Being Affected By The Material And Thickness Of The Fabric. It Also Has The Function Of Unfolding The Wrinkles Of The Fabric, Ensuring That The Fabric Is Flat And Centered Before Entering The Processing Equipment.

Performance Characteristics

● Three Expansion Rollers Can Fully Unfold The Fabric; The Contact Surface Between The Fabric And The Expanding Roller Can Be Easily Adjusted.

● Infrared Detector, Full Range Non-Contact Detection Of Fabric Deviation;

● The Cylinder Drives The Correction Roller To Stabilize The Fabric In The Middle Position;

● Easy To Operate, Sensitive In Action, And Reliable In Operation.

Technical Parameter

● Stainless Steel Expansion Roller: φ 100mm * 3 Pieces, Wire Wound φ 4mm, Round Or Flat Wire

● Motor Power: 750w * 1 Unit, 550w * 1 Unit (Depending On Door Amplitude)

● Infrared Control System: One Set (Many Options Available)

● Centering correction drive: cylinder driven, air pressure 3kgf/cm ²

● Deviation Correction Roller Limit Device: One Set

● Power Supply: Three-Phase 380v Ac 50hz

● Installed Capacity: Dynamic 1.5kva